Maintenance for Drip Dispersal Septic Systems

Maintenance for a drip dispersal septic system is a three part attack. The maintenance should be broken down by pretreatment, pumping and hydraulic unit, and absorption area or drip dispersal area.

Pretreatment usually consists of either septic tanks or aerobic treatment plants. Both require constant monitoring. Septic tanks are a passive type of treatment and require less maintenance. Septic tanks are sized based on the number of bedrooms in a dwelling¾not by the quantity of proposed occupants or the water usage by them. Management cycles and pumping are dependent on the size of thetankage, volume of wastewater the system is receiving, the amount of solids produced, and the percent of solids digested or retained.

Based upon these facts, it is impossible to determine an exact schedule of when to pump a tank or clean effluent filers in them

without constant monitoring. The best rule of thumb is to cleanout the septic tank when the floatable solids (scum) thickness added to settable solids (sludge) thickness are equal to one third of the liquid depth of the tank. They should be monitored every six months and maintenance are required by the monitoring.

Aerobic treatment plants require constant monitoring and manufacturer specific maintenance. Usually the monitoring and maintenance is required to be completed on a six month interval in order for the specific type of treatment to maintain its NSF-40 (National Sanitation Foundation) approval. Some intervals require measurements of mixed aeration areas with a graduated cylinder to determine the suspended solids. When suspended solids reach a certain amount, the system must be pumped and cleaned. Hollow aerator shafts must be pulled out, checked and cleaned. Fixed media in the aeration chamber must be checked and once per year, bubble scrubbed with a blower. Pumping in these treatment tanks usually occurs once every three years as long as the system has been operation properly. Overall, they usually require maintenance ever six months.

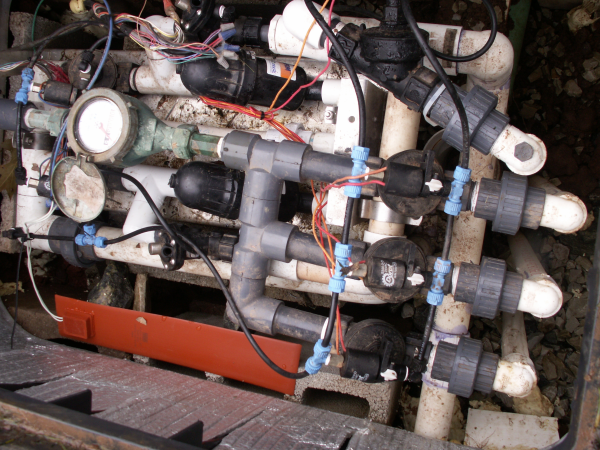

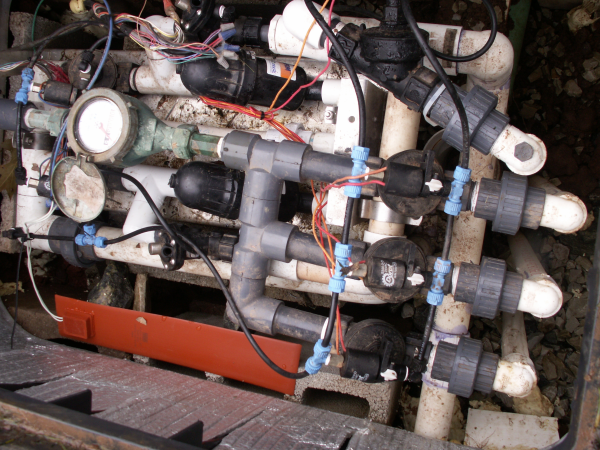

Hydraulic units and pumps need to monitored and screens and filters cleaned every six months. Although disc filters located in the hydraulic unit clean themselves every time the unit cycles, it also cleans itself every five minutes of operation. Screens located on the pump should be cleaned if monitoring information indicates clogging. The hydraulic unit along with its computer control panel should have all of its functions checked to make sure it is operating correctly. All of its functions should timed and compared to the previous interval readings and also startup readings.

The hydraulic unit has a water usage meter located in it. The reading on this meter should be monitored every time the unit is serviced and compared to previous readings. A quick calculation should be made to make sure the unit is not being asked to handle more wastewater than it was designed to. A heat strip located on the bottom of the hydraulic unit should be checked to make sure it is operating properly.

The drip tubing or absorption area needs to be checked every six months as well. Drip absorption areas have between two and four zones. Air release valves need to be checked for proper operation. There are usually two in each zone. Zone dosing and forward flush timing must also be checked and compared to timing obtained at startup. Checking the timing can determine if check valves buried in the ground need to be serviced or replaced. Left alone and not fixed can cause a zone to operate at double its designed capacity thereby creating a failure that may not be able to be fixed.

As you can see, six months seems to be the best interval for monitoring and maintenance. OnSite Management is able to provide its clientele a very cost effective maintenance plan that offers the best blend of monitoring and maintenance.

Please coment on your experiences!